Release agent HC-K5618TS

• Transparent clear liquid

Using high-viscosity white oil and special silicone paste as the main raw materials, it has good self-emulsifying properties, with good stripping properties,with good blade lubrication, and greatly improves the softness and gloss of paper.

keyword:

Classification:

Products Details

Product Name

Release agent HC-K5618TS

Product introduction

C-K5618TSis made of high viscosity white oil and characteristic silicone paste as the main raw material, good self-emulsification performance, can effectively achieve Good thermal conductivity, lubricating scraper; it can form protective coating against cylinder surface and roller surface. thus ensuring the production of ideal of paper products.

HC-K5618TS effectively protects the cylinder and roll surface and prolongs the life of the doctor blade.

HC-K5618TS fundamentally improves the contact between the paper and the cylinder, gives the paper good peeling performance, and greatly improve the softness and gloss of the paper.

Characteristic description

HC-K5618TS is mainly used to remove the "sticky cylinder" phenomenon in the paper production process and reduce the paper perforation and paper breakage. The main function of HC-K5618T is to remove the phenomenon of "sticky cylinder" in the papermaking process and reduce the perforation and paper breakage.

HC-K5618TS can effectively prevent paper scraping, perforation and paper breakage when used for copying household paper, and can make the paper expand moderately. HC-K5618TS can effectively prevent paper scraping, perforation and paper breakage, and make the paper expand moderately; improve the softness and handfeel.

HC-K5618TS can effectively solve the problem of sticky cylinder caused by sizing when used in the production process of cultural paper.

HC-K5618TS can make the surface of the drying cylinder as bright as new, no glue stick, reduce paper breakage, and greatly improve the product quality.

Technical parameters

Appearance:Colorless to slightly yellow liquid

Water solubility:easily dispersed, self-emulsifying

Density (20℃, g/cm3):0.75~0.95

Operating viscosity(40℃,mm2/s):20~38

Usage and dosage

HC-K5618TS The dosage in cultural paper is 50 to 100ppm;

The dosage in household paper is from 50 to 200ppm;

HC-K5618T's is sprayed on the surface of the drying cylinder by spraying and gradually forms a specific coating on the surface of the drying cylinder.

Packaging and storage

HC-K5618TS can be packed in 200 liter or 1000 liter plastic drums or special packaging as required, stored in a cool and airy place indoors. Store in a cool and ventilated place, avoid sunlight, storage temperature is 5~38°C, storage period is one year.

Safety matters

It is recommended to wear appropriate personal protective equipment when using, such as: gas mask, rubber gloves, safety goggles, etc.

Avoid eye and skin irritation. Avoid mixing with strong acid or strong alkaline, reducing substances.

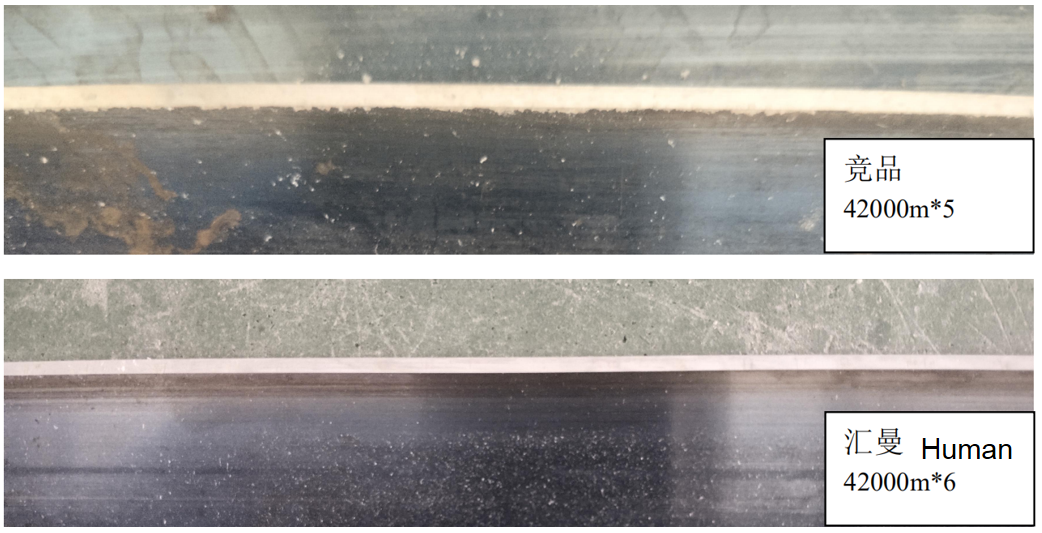

Yankee dryer creping chemicals application

HUMAN Creping coating chemicals advantages:Effectively lubricate the blade ,extend the service life ,reduce the creping rate,promote production and better protect the drying cylinder.

Advantages of HUMAN Creping coating chemicals : The coating is even and complete and have no adhesion on the adges sides,Reduced breaks,increased paper production,Improved moisture control,Reduced steam consumption.

Related Products