Release agent HC-5618

• Light yellow oily liquid

Dryer coating realease aids compounded with medical liquid paraffin, has strong stripping and emulsifying properties.

keyword:

Classification:

Products Details

Product Name

Release agent HC-5618

Product introduction

HC-5618 is a baking cylinder coating stripper compounded from medical liquid paraffin wax processing.

HC-5618 does not contain aromatic hydrocarbons and anionic surfactants and is nonionic in aqueous solution.

HC-5618 is a product that controls coating and adhesion status. Stabilizes wrinkles and improves the strength of the paper sheet.

HC-5618 has strong peeling and emulsifying properties. Capable of reducing coating and adhesion and regulating different properties of products Indicators

Characteristic description

HC-5618 can improve the heat transfer performance.

HC-5618 has good tribological and lubricating properties, which can prolong the life of squeegee.

HC-5618 has been tested and proven in the production of paper and cardboard, and it meets the hygiene standards of food and household consumer products. It is a high-grade YanKee dryer coating stripper, widely used in high-speed household paper machine, especially for various requirements of toilet paper. It is widely used in high speed tissue machines, especially for the production of tissue machines with various requirements.

HC-5618 high-grade YanKee cylinder coating stripper is sprayed on the cylinder surface and gradually forms a specific coating on the cylinder surface.

HC-5618 fundamentally improves the contact between the paper and the dryer, giving the paper good peeling properties and significantly improve the surface smoothness and gloss of the paper

Technical parameters

Appearance: light yellow liquid

Water solubility: easy to disperse, self-emulsifying

PH value: 5.0~6.5

Viscosity mPa.s (25℃): ≤15~3

Usage and dosage

HC-5618 is used in conjunction with HUMAN's tackifier and is usually sprayed directly onto the surface of the cylinder with a spray unit, or it can be added to the pulp or sprayed onto the felts. It can also be added to the pulp or sprayed on the felts. The ideal combination and application method can be determined in consultation with HUMAN technical The ideal combination and application method can be determined in consultation with HUMAN technical staff to ensure the best fit with the paper machine.

Store the solution long enough to bring it to room temperature before use. Use according to the safe use of the liquid.

Packaging and storage

HC-5618 can be packed in 200kg or 1000l plastic drums, or special package according to the need, and stored in a cool and airy place indoors. Store in cool and ventilated place, avoid sunlight, storage temperature is 5~38°C, storage period is one year.

Safety matters

It is recommended to wear appropriate personal protective equipment when using, such as: gas mask, rubber gloves, safety goggles, etc.Avoid eye and skin irritation. Avoid mixing with strong acid or strong alkaline, reducing substances.

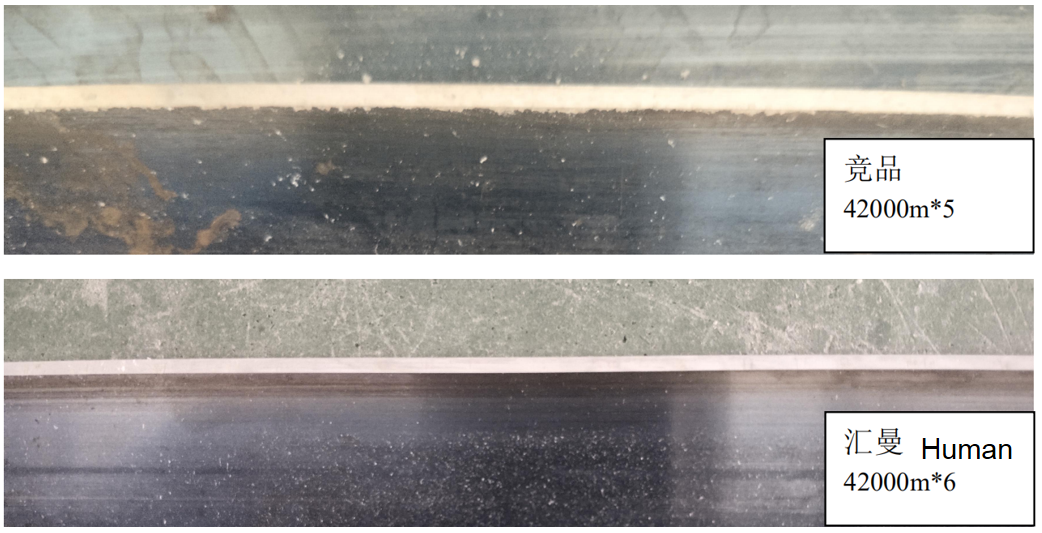

Yankee dryer creping chemicals application

HUMAN Creping coating chemicals advantages:Effectively lubricate the blade ,extend the service life ,reduce the creping rate,promote production and better protect the drying cylinder.

Advantages of HUMAN Creping coating chemicals : The coating is even and complete and have no adhesion on the adges sides,Reduced breaks,increased paper production,Improved moisture control,Reduced steam consumption.

Related Products